Material Solutions

Our Future Capability at GKN Kongsberg

As global demand for better performance, reduced weight, and improved sustainability keeps rising, materials technology plays a crucial role in shaping the next generation of products. At GKN Aerospace Kongsberg, Material Solutions is more than a technological initiative – it is a strategic investment in our future competitiveness.

Laser Directed Energy Deposition (L-DED-w/p)

The products we develop solutions for in Kongsberg will mainly fall within the product families belonging to our Centre of Excellence. Here, we will focus on both machining and additive manufacturing of various components, such as low-pressure turbine housings. These typically have a diameter of 600–1200 mm and a height of 200–600 mm. They also feature functional geometry on the exterior, which requires thicker billets and results in increased machining.

To meet these challenges, we have established capabilities within additive manufacturing, also known as 3D printing. Today, we print both external and internal geometries onto existing billets, and our long-term goal is to produce the entire billet from the ground up. This development takes place in close collaboration with our customers, the aircraft engine manufacturers, enabling step-by-step product qualification.

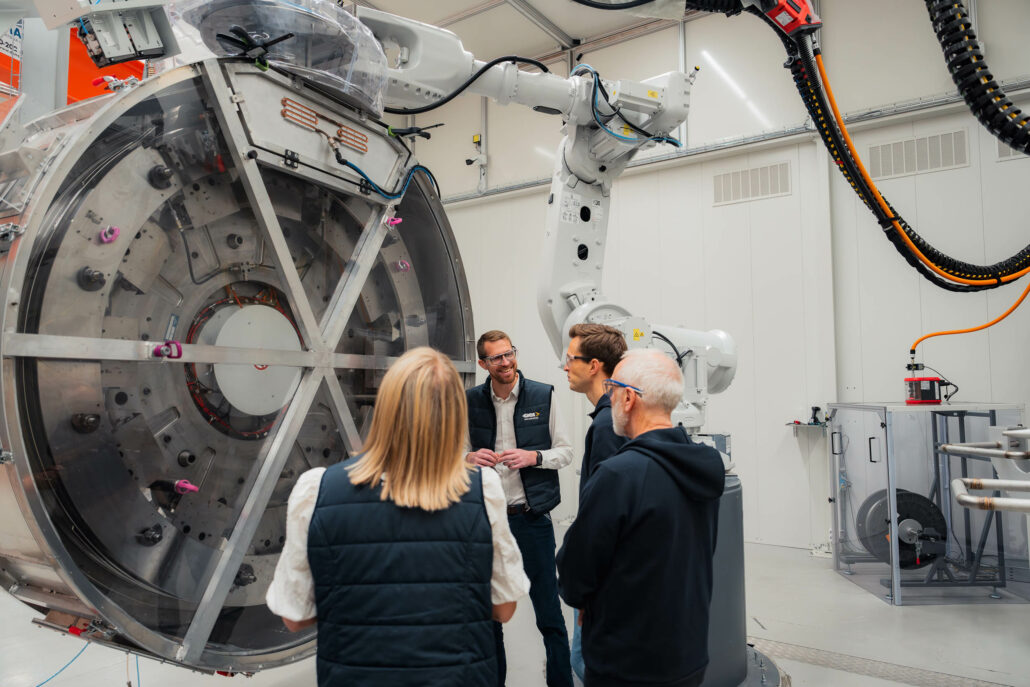

The technology we are implementing is Laser Directed Energy Deposition with wire or powder (L-DED-w/p), delivered by Permanova Lasersystem, a part of the GKN Aerospace family.

One of the machines from Trollhättan

The Road Ahead

Rather than being the final goal, Material Solutions represents the launchpad for future ambitions. We are still in the early stages, but results are already evident through pilot projects and cross-functional development teams.

Kongsberg’s first L-DED-w cell will be operational in 2026. As we move towards 2030, we will continue to expand our efforts and drive growth.

We invite everyone to join us on this journey: partners, customers, and colleagues. Together, we are building the capabilities of tomorrow – already today.

High Technology and Opportunities in Kongsberg

In Kongsberg, GKN Aerospace is a key player in high-tech manufacturing for the aerospace industry. Today, we focus on precision machining and producing advanced aircraft engine and structure components. This work requires high accuracy and technical expertise, enabling aircraft to fly farther, faster, and more efficiently.

GKN Aerospace Norway (GAN) continuously works towards innovation, sustainability, and ongoing development. We already use additive manufacturing and 3D printing in our production, which has helped us reduce material waste and energy consumption.

If you seek a job in Kongsberg, GAN offers exciting career opportunities in manufacturing engineering, quality control, and technological development. We are always looking for dedicated and skilled workers, engineers, and technicians who want to be part of a global company with strong local roots.

Join GKN Aerospace Norway and help shape the future of aviation technology.